by Giovanni Carrera, 3/03/2022

ESP32 has two 12-bit SAR (Successive

Approximation Register) ADCs which are able to convert up to 18 analog inputs. The

maximum value to convert is equal to the reference value Vref, for the ESP32 it

is about 1 V, but it can vary between 950 and 1100 mV. It is possible to use

voltages higher than Vref by attenuating the input. The ESP32 has four possible

attenuation options:

|

Attenuation |

input voltage range |

|

ADC_ATTEN_DB_0 |

100 mV ~ 950 mV |

|

ADC_ATTEN_DB_2_5 |

100 mV ~ 1250 mV |

|

ADC_ATTEN_DB_6 |

150 mV ~ 1750 mV |

|

ADC_ATTEN_DB_11 |

150 mV ~ 2450 mV |

In my case, the default attenuation

is 0 dB, with an input range of about 68 to 995 mV. For better accuracy it is

recommended not to use attenuation, ie 0 dB, and to employ the pins of ADC1, I

used GPIO34.

Figure 1 shows a fairly serious

problem on low input levels: below 68 mV the converter output gives zero,

creating a dead zone and strong non-linearity.

|

| figure 1 |

So I tried to think of a circuit able to accept

an input down to zero volts and to output a signal that can be converted

without the drawbacks described above. If, for example, we want to have the

following conditions:

Vin = 0 mV → Vout = 100 mV

Vin = 3000 mV → Vout = 1000 mV

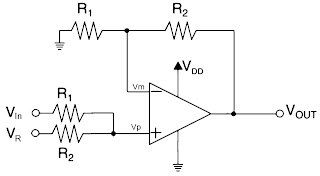

The summer circuit, shown in figure 2, realizes

these conditions very well.

|

| Figure 2 |

Remembering that for an ideal op amp the inputs

are at the same potential, so Vm

= Vp , its output

voltage is:

Vout = Vp(1+R2/R1) (1)

Where Vp is the voltage on the non-inverting

input of the operational amplifier:

Vp

= Vin –(Vin -VR)*R1/(R2+R1) (2)

In the case of VIN = 0, we

have:

Vp = VR*R1/(R2+R1)

Setting VR = 100 mV, R1 = 300 kΩ and R2 = 100 kΩ, we obtain:

Vout = Vp*4/3

Vp = VR*3/4 = 75

mV

Therefore the output voltage is:

Vout = VR*3/4*4/3 = VR = 100 mV

In the case of VIN = 3000 mV, from

the expression 2 we have:

Vp

= (VIN - VR) *R2/(R2+R1) + VR

And, substituting, we have:

Vp = 3000 –(2900)*3/4= 825 mV

So the output voltage is:

Vout = Vp*4/3 =1100

Setting R1 = 330 kΩ and R2 = 100 kΩ, the conditions imposed are almost perfectly met:

Vin = 0 mV → Vout = 100 mV

Vin = 3000 mV → Vout = 1009 mV

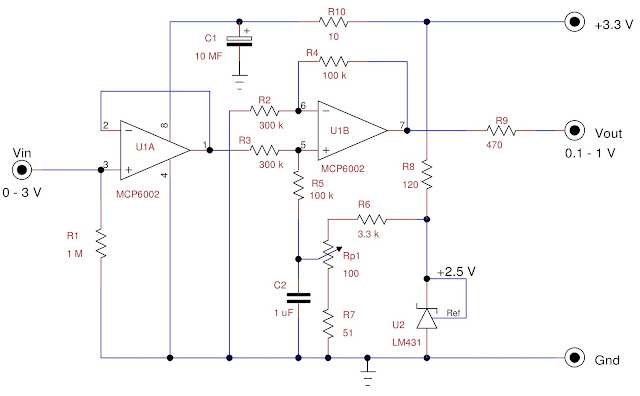

Figure 3 shows the wiring diagram of my

prototype. The operational amplifier U1A serves as a voltage follower, U1B as

an adder, and U2 provides a stable reference voltage. In my prototype I used

the values indicated in the diagram, but I suggest to use the value of 330 kΩ for R2 and R3.

Rail-to-rail operational amplifiers, such as

the one indicated, are particularly suitable for this application.

|

| Figure 3 |

Now you need to perform a calibration. First

you have to write a program that reads the values of an analog pin, in my case

IO34, and prints them. You can use the Arduino IDE or MicroPython, as in my

case.

Put a jumper between the input and ground for

Vin = 0, then slowly turn the trimmer Rp1 until you begin to see numbers other

than zero.

|

| Figure 4 |

We then connect the Vin input to a low-noise,

stable voltage generator, checking the voltage with an accurate digital

voltmeter. I take the various measurements and put them on an Excel-like

spreadsheet to do a linear regression like the one in figure 4. As can be seen,

the results were excellent, with an R2 very close to one. To have

the millivolts output, you need to invert the axes of the regression and insert

the following expression:

mV = NADC*0.713780799+3.473077

Obviously these values are valid in my case.

Components

list

|

component |

description |

component |

description |

|

R1 |

1 MW ± 1% metal film |

R10 |

10 W ± 5% |

|

R2, R3 |

330 kW ± 1% metal film |

Rp1 |

100 Ω multi-turn trimmer |

|

R4, R5 |

100 kW ± 1% metal film |

C1 |

10 µF,35V Aluminum

electrolytic |

|

R6 |

3.3 kW ± 1% metal film |

C2 |

1 µF,25V ceramic AVX |

|

R7 |

51 W ± 1% metal film |

U1 |

MCP6002, dual rail-to-rail op amp |

|

R8 |

120 W ± 5% |

U2 |

TL431, shunt voltage reference |

|

R9 |

470 W ± 5% |

|

|

Program

This program, written in MicroPython, acquires

100 samples at 500 Hz, makes the statistics and prints them. I took the average

value while also observing the standard deviation of the measurements which

must be minimal.

# Program TestADSer.py to test display

and ADC

# Giovanni Carrera, 03/03/2022

from machine import Pin,ADC

from time import sleep,sleep_ms

import math

ch1 = ADC(Pin(34)) #

initializes the analog input

ndata = 100

arr = [0 for i in range(ndata)]

while True:

vmean = 0

vqmean = 0

vmax = 0

vmin = 5000

for x in range(0,ndata):

arr[x] = int(ch1.read())

if arr[x] > vmax :

vmax = arr[x]

if arr[x] < vmin :

vmin = arr[x]

vmean += arr[x]

vqmean += arr[x]**2

sleep_ms(2)

vmean /= ndata # mean value

vqmean /= ndata # mean of quadratic values

k = vqmean - vmean**2

if k >= 0 :

StDev = math.sqrt(k)

else :

StDev = 0

print('Analog ch = IO34')

print('Max =' + str(vmax))

print('Min=' + str(vmin))

print('Mean=' + str('%.1f' %vmean))

print('Sdev=' + str('%.1f' %StDev))

print()

sleep(1)

Reference

1.

“AN682 Using Single Supply

Operational Amplifiers in Embedded Systems”, Bonnie Baker, Microchip Technology

Inc. , 2000

2.

“Analog to Digital Converter

(ADC)”, https://docs.espressif.com/projects/esp-idf/en/latest/esp32/api-reference/peripherals/adc.html#adc-calibration

“ESP32 Technical Reference Manual, Version 3.0”, Espressif Systems

This is an interesting article for me, however the code for calibration is written in MicroPython. I would appreciate very much an Arduino code for Arduino Ide. Would that be possible for you to publish?

ReplyDeleteThis simple program print an ADC value every 0.5 s:

Deletevoid setup(void) {

Serial.begin(115200);

}

void loop() {

int val = analogRead(34);

Serial.println(val);

delay(500);

}